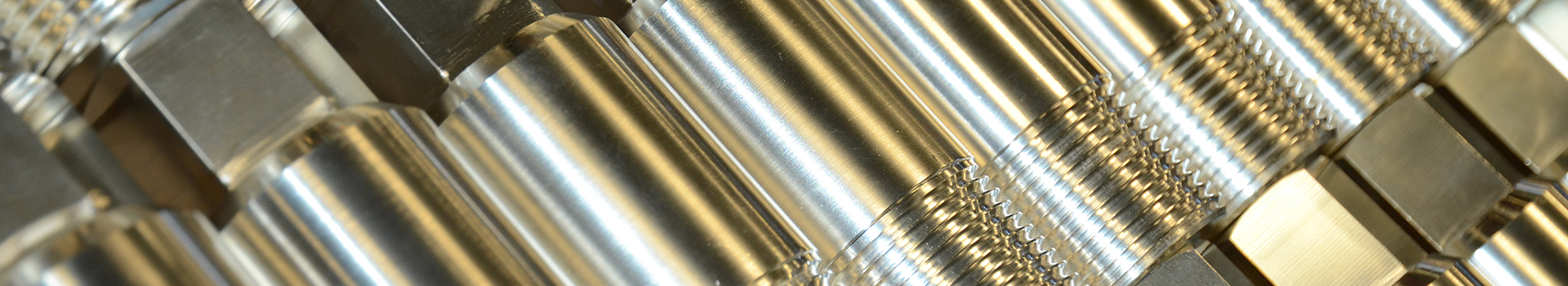

Our processes

Our process provides bright and mat tin plating at 99.9% purity, compliant to ASTM B545 and MIL-T-10727. Depending on request, barrel or rack plating on base metal as aluminum, brass, copper, steel and stainless steel can offer to meet your expectation.

Typical application:

- To provide corrosion and tarnish resistance.

- To be used as precoating on basis metal to facilitate the soldering.

- To improve anti-galling properties.

- To provide the low contact resistance when bolting and joining of bus bar, terminal and electrical component.

Design consideration:

- Tin coating begins to oxide rapidly in air at 150°C and melt at 232°C.

- Tin coating changes structures and loses adhesion when exposed to temperature below -40°C.

- Tin whiskers (metal filament) grows spontaneously on the tinned surface after time and these can cause short-circuit failure on electronic system when conductor components are closely spaced.

ASTM B545

Class A – 0.0001” (2.5 µm)

Class B – 0.0002” (5 µm)

Class C – 0.00032” (8 µm)

Class D – 0.0006” – 0.0008” (15 µm – 20 µm)

Class E – 0.0012” (30.5 µm)

Class F – 0.00006” (1.5 µm)

MIL-T-10727

Class 1 – Electrodeposited (refer to ASTM B545)

Class 2 – Hot dipped

SILVER

Our process provides bright and semi-bright silver plating at 99.9% purity, up to 0.004” (101.6 µm) of coating thickness compliant to ASTM B700 and QQ-S-365. Depending on request, barrel or rack plating on base metal as aluminum, brass, copper, steel and stainless steel can offer to meet your expectation.

Typical application:

- To be used as precoating on basis metal to facilitate the soldering.

- To prevent galling or seizing on metal surface and thread

- To improve adhesion, ductility and soundness on bearing surface

- To provide the low contact resistance when bolting and joining of bus bar, terminal and electrical component in high current.

Design consideration:

- Silver whiskers (metal filament) grows spontaneously on the silver coating surface after time and these can cause short-circuit failure on electronic system when conductor components are closely spaced. The major environmental factor to initiate the growth is relatively low concentration of Hydro Sulfide (H2S).

- Silver tarnishes readily in the presence of sulfur in urban atmosphere. Protection from tarnish becomes very important for decorative objects and electrical components.

ASTM B700 Classification:

Silver purity:

Type 1: 99.9% min

Surface appearance:

Grade B: Bright, obtained by brightener

Grade D: Semi-bright

Class N: Without tarnish resistant adding.

Class S: With tarnish resistant adding.

Minimum thickness guideline:

0.00004 (1 µm) For soldering.

0.0001 (2.5 µm) For contact connector.

0.0002 (5 µm) For thermocompression bonding and domestic hollowware.

0.0004 (10 µm) For medium-quality of thermocompression bonding and domestic hollowware.

0.0008 (20 µm) For high-quality of domestic hollowware and flatware.

0.0015 (40 µm) For severe wear resistance such as bearing, sliding and rotating electrical contact.

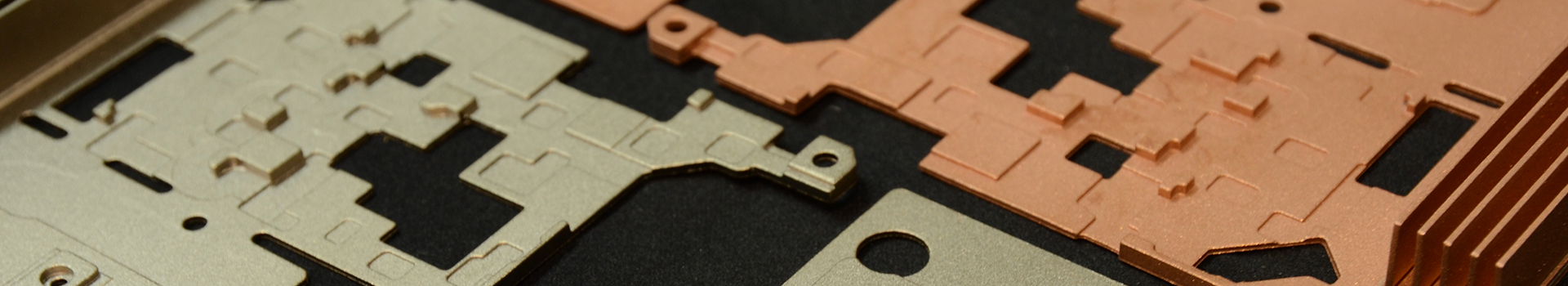

COPPER

Our process provides bright electrodeposited copper plating compliant to MIL-C-14550. Depending on request, barrel or rack plating on base metal as aluminum, copper, brass, invar, kovar, steel, stainless steel and tellurium copper can offer to meet your expectation.

General application:

Copper is mostly used as an undercoating for other plated metals to obtain a better corrosion resistance and adhesion. To make it even more corrosion protective, nickel coating is added as a combination. It is also commonly found in industries as automotive, electronics and renewable energy because of his excellent electrical conductivity and heat transfer properties.

Design consideration:

Copper is a highly active metal and easily tarnish, for this reason, coating of copper is mostly used as an undercoated.

MIL-C-14550 – Copper plating electrodeposited

Class 0 – 0.001 to 0.005 (75 to 127 µm): For heat treatment stop-off

Class 1 – 0.001 (75 µm): For carburizing and decarburizing shield and printed circuit board plated through holes or as specified on the engineering drawing.

Class 2 – 0.0005 (12.7 µm): As undercoating for nickel and other metals.

Class 3 – 0.0002 (5 µm): To prevent basis metal migration into tin layer to poison solderability.

Class 4 – 0.0001 (2.5 µm): Same as class 3

NICKEL

Our process provides bright and semi-bright electrodeposited nickel compliant to QQ-N-290, electroless nickel with medium and high phosphorus, compliant to ASTM B733 and MIL-C26074. Depending on request, barrel or rack plating on base metal as aluminum, brass, copper, steel and stainless steel can offer to meet your

Electroless nickel vs electrodeposited nickel:

Contrary to electrodeposited, electroless nickel is a chemical process without the use of electric current. There are the major differences between electrodeposited nickel and electroless nickel:

- The nickel purity of electrodeposited is greater than 99% and electroless is 92% nickel with 8% phosphorus.

- On the complex components, ridges or sharp edges profile, electroless coating can be accurately and uniformly deposited than electrodeposited.

- Coating hardness of electroless nickel phosphorus as plated: 400-500 HV (45-50 HRC)

- Coating hardness of electroless nickel phosphorus with heat treated: 700-1000 HV (60- 70 HRC)

- Coating hardness of electrodeposited nickel as plated: 150-250 HV (80 HRB-25 HRC)

- The electrodeposited process costs less than electroless.

Electroless nickel-phosphorus

General application:

Electrodeposited and electroless nickel are widely used for protection against corrosion and abrasion/wear in the industries as automotive, aircraft, chemical, electronic, electric motor, mining, printing, power generation, pulp and paper, oil and gas, etc.

Design consideration:

Because of the different choices and applications of the nickel coating, designer must be careful when choosing the kind of coating for the specific application.

Electrodeposited nickel (sulfate/chloride)

QQ-N-290 – Electrodeposited nickel plating on steel, copper and zinc (castings)

Classification:

Class 1: Corrosion protective

Class 2: Engineering plating

Thickness:

Grade A: 0.0016 (40 µm)

Grade B: 0.0012 (30 µm)

Grade C: 0.0010 (25 µm)

Grade D: 0.0008 (20 µm)

Grade E: 0.0006 (15 µm)

Grade F: 0.0004 (10 µm)

Grade G: 0.0002 (5 µm)

Nickel-plating solutions and properties of deposit.

Type:Sulfate/chloride

Composition:Nickel sulfate, Nickel chloride, boric acid

Vickers Hardness (100g load):150–280

Tensile Strength (MPa):480–720

Elongation (%):5–25

Electroless nickel-phosphorus

ASTM B733 – Electroless nickel

Phosphorus contained on nickel coating:

Type IV: 5 to 9% – Medium phosphorus

Type V: 10% and above – High phosphorus

Post heat treatment class:

Class 1: As deposited, no heat treatment.

Class 2: Heat treatment at 260 to 400°C to produce the minimum hardness of 850 HK100

Type I: 260°C for 20h / 285°C for 16h / 320°C for 8h / 400°C – 1h

Type II: 350 to 380°C for 1h

Type III: 360 to 390°C for 1h

Type IV: 365 to 400°C for 1h

Type V: 375 to 400°C for 1h

Class 3: Heat treatment at 180 to 200°C for 2 to 4h to improve coating adhesion on steel and reduce the risk of Hydrogen embrittlement.

Class 4: Heat treatment at 120 to 130°C for 1 to 6h to increase adhesion of heat treatable for age hardened aluminum alloys and carburized steel.

Class 5: Heat treatment at 140 to 150°C for 1 to 2h to improve coating adhesion for aluminum, non-age hardened aluminum alloys, copper and copper alloys.

Thickness coating requirements for service condition:

SC0 (minimum thickness): 0.000004 (0.1 µm)

SC1 (light service): 0.0002 (5 µm)

SC2 (mild service): 0.0005 (13 µm)

SC3 (moderate service): 0.001 (25 µm)

SC4 (severe service): 0.002 (75 µm)

GOLD

Our process provides matte and bright gold plating Type compliant to MIL-G-45204. Depending on request, barrel or rack plating on base metal as aluminum, brass, copper, nickel and stainless steel can offer to meet your expectation.

Gold is the plating material with the best corrosion resistance and therefore one of the most commonly used for high performance electrical contacts. The basic function of gold coating in electrical contacts is the protection against corrosion and fretting corrosion. For soldering, a thin high purify soft gold coating is preferred. A minimum thickness of 0.00005 inch (1.3 µm) and a maximum thickness of 0.0001 inch (2.5 µm) shall be plated.

Design consideration:

The critical points with gold coating are the wear resistance and the materials cost.

MMIL-G-45204 – Gold Plating (Electrodeposited)

Type I – 99.7% gold min. (Grade A, B, C)

Type III – 99.9% gold min. (Grade A only)

Grade A – 90 Knoop max.

Grade B – 91-129 Knoop

Grade C – 130-200 Knoop

Grade D – 201 Knoop and over

Class 00 – .00002’’ min.

Class 0 – .00003’’ min.

Class 1 – .00005’’ min.

Class 2 – 00010’’ min.

Class 3 – 00020’’ min.

Class 4 – 00030’’ min.

Class 5 – 00050’’ min.

Class 6 – 00150’’ min.

IRRIDITE

Our process provides aluminum chromate conversion coatings compliant to MIL-DTL-5541 Type II, class 1A and 3. Depending on request, barrel or rack plating on base metal as aluminum and aluminum alloys can offer to meet your expectation.

Type I – Compositions containing hexavalent chromium for providing corrosion protection on unpainted products, as well as improve adhesion of paint finish systems on aluminum and aluminum alloys. The conversion coatings covered by this specification exceed commercially available products due to the nature of their use on aircraft.

Type II – Compositions containing no hexavalent chromium.

Class 1A – For maximum protection against corrosion, painted or unpainted on aluminum and aluminum alloys. Coatings of this type may be used, for example, on tanks, tubing, and component structures where paint finishes are not required for interior surfaces but are required for the exterior surfaces.

Class 3 – For protection against corrosion where low electrical resistance is required for electrical and electronic applications.

Thickness: Coating thickness is varied by immersion time. Generally, thickness can be obtained between 0.00001 to 0.00004 inches and it cannot measure by conventional method due to the extremely thin of chemical film coating. Class 3 coatings are more susceptible to corrosion because they are thinner than class 1A.

PASSIVATION

Our process provides passivation compliant to ASTM-A-967, method Nitric 2. Depending on request, barrel or rack plating on base metal as Stainless Steel can offer to meet your expectation. Passivation is a chemical treatment applied to stainless steel parts to provide resistance to oxidation, rusting and mild chemical attack. The table below show different base material with the passivation treatment required.

Passivation Treatment

| Grade | Nitric 1 | Nitric 2 | Nitric 3 | Nitric 4 |

|---|---|---|---|---|

| Austenitic | ||||

| s20100 | – | – | ||

| s20200 | – | – | ||

| s30100 | – | – | ||

| s30200 | – | – | ||

| s30400 | – | – | ||

| s30403 | – | – | ||

| s30409 | – | – | ||

| s30430 | – | – | ||

| s30451 | – | – | ||

| s30500 | – | – | ||

| s30800 | – | – | ||

| s30900 | – | – | ||

| s30908 | – | – | ||

| s30940 | – | – | ||

| s31000 | – | – | ||

| s31400 | – | – | ||

| s31600 | – | – | ||

| s31603 | – | – | ||

| s31609 | – | – | ||

| s32100 | – | – | ||

| s32109 | – | – | ||

| s32109 | – | – | ||

| s34700 | – | – | ||

| s34709 | – | – | ||

| Duplex | ||||

| s32900 | – | – | ||

| Ferritic | ||||

| s40500 | – | – | ||

| s40900 | – | – | ||

| s42900 | – | – | – | |

| s43000 | – | |||

| s43400 | – | – | ||

| s43600 | – | – | ||

| s44200 | – | – | ||

| s44600 | – | |||

| s44627 | – | – |

| Grade | Nitric 1 | Nitric 2 | Nitric 3 | Nitric 4 |

|---|---|---|---|---|

| Free Machining | ||||

| s30300 | – | |||

| s30323 | – | |||

| s30310 | – | |||

| s30330 | – | |||

| s30345 | – | |||

| s30360 | – | |||

| s34720 | – | |||

| s34723 | – | |||

| s43020 | – | |||

| s43023 | – | |||

| s44020 | – | |||

| s44023 | – | |||

| Martensitic | ||||

| s40300 | – | – | ||

| s41000 | – | – | ||

| s41400 | – | – | ||

| s41600 | – | |||

| s41623 | – | |||

| s42000 | – | |||

| s43100 | – | – | ||

| s44003 | – | – | ||

| s44004 | – | – | ||

| Percipitation | ||||

| Hardening | ||||

| k66286 | – | – | ||

| s13800 | – | – | ||

| s15500 | – | – | ||

| s15700 | – | – | ||

| s17400 | – | – | ||

| s17700 | – | – | ||

| s35500 | – | – | ||

| s36200 | – | – |